Simply Better

smartGLEIT® has been successful in the specialty lubricants market for more than 20 years. We develop, produce and sell specialty lubricants – the problem solvers even for particularly difficult cases. microWHITE greases and lubrication pastes are famous for their performance in particular tricky areas of tribology.

smartGLEIT® 700-Series

…and Fretting Corrosion is History

Fretting Corrosion – A Friction- and Wear-Phenomenon

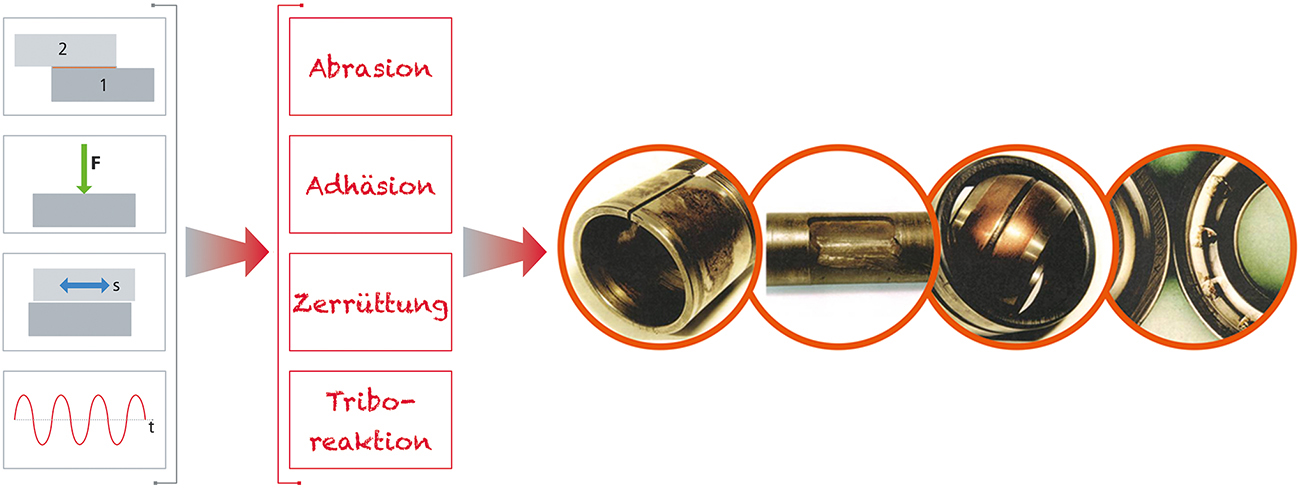

Fretting corrosion, an extremely efficient wear mechanism, is induced by oscillating movements with low amplitudes. A characteristic of fretting corrosion is the combination of all main wear mechanisms as abrasion, adhesion, fatique and tribooxidation are part of the overall damage. Depending on the individual tribological conditions their level of contribution to the overall damage may vary. In relation with fretting corrosion different terms are used in practice:

„Vibrational wear, false brinelling, corrosive wear, tribooxidation, chafing corrosion, ripple damage, etc.“.

Typically, the mechanical stress – not to be confused with ‘normal’ corrosion in the presence of water – creates corrosion products at the friction contact point, different variants of iron oxide e.g. wüstite, hematite, maghemite, etc. Anyway, the occurrence of fretting corrosion will lead inevitably to rapid failure of the mechanical system.

The smartGLEIT 700-Series

The New Benchmark Against Fretting Corrosion

Pastes and Greases with Added Value

- The smartGLEIT® 700 Series – new, innovative lubrication-pastes*, grease-pastes** and greases for all applications lubricated with greases or pastes

- Based on the new generation of white solid lubricants a complete product family was created – for each application the right lubricant for assembly, running in or lifetime lubrication:

‣ Lubrication-Pastes PSV – Series

‣ Grease-Pastes FSV – Series

‣ Greases GSV – Series - Common lubricant standards are met – therefore the products can be applied similar to ‘normal’ greases or lubrication pastes.

* Lubrication-paste with high solids content = PSV

** Grease-paste with medium solids content = FSV

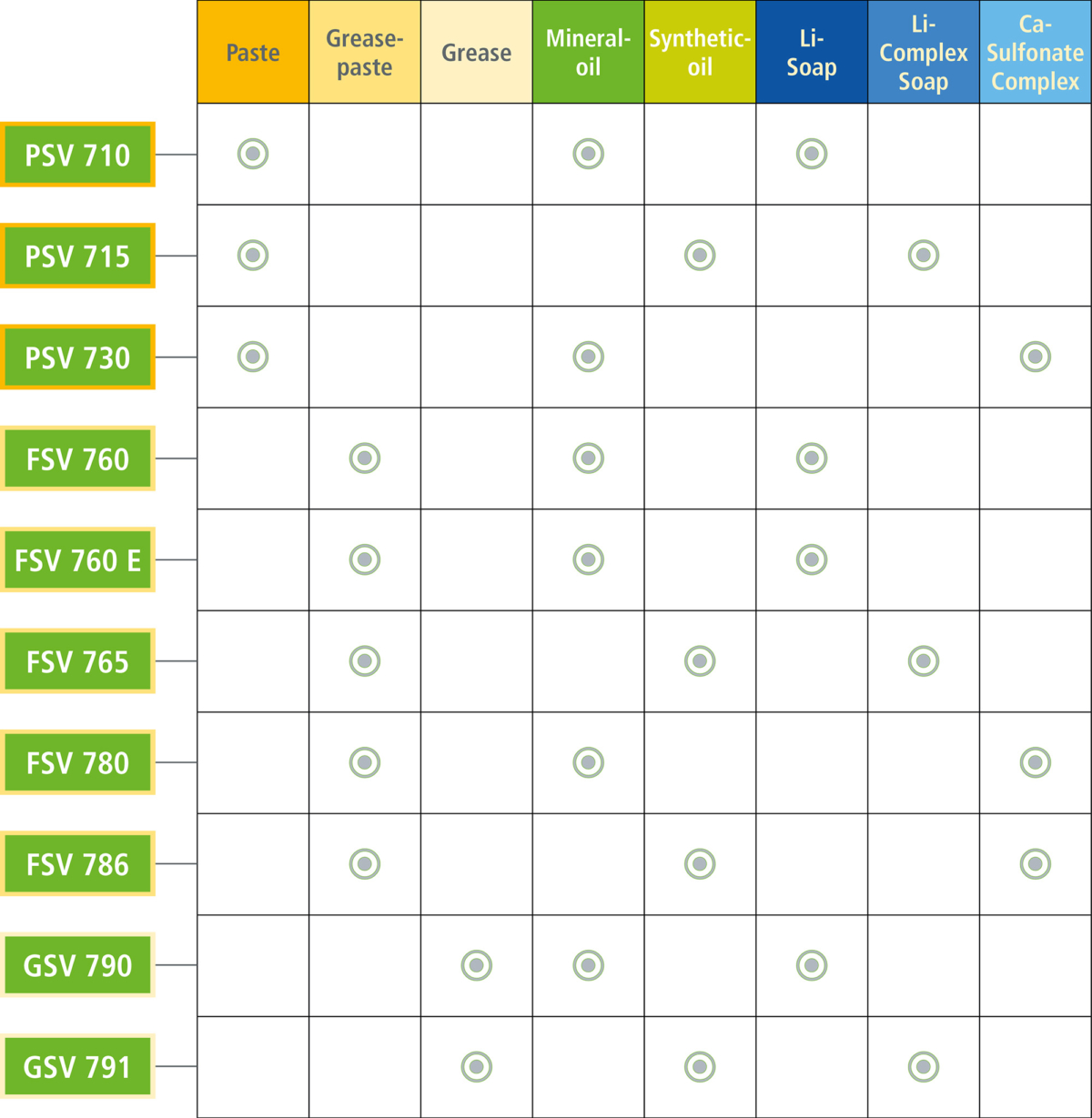

Product Overview